What are the ten common problems and the corresponding solutions?

来源:Dongguan Yanghan Industrial Co., Ltd. 时间:2020-12-02

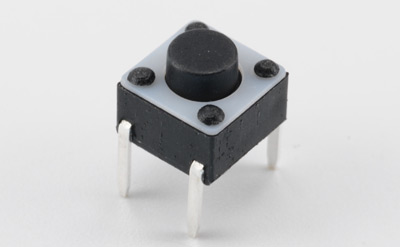

Touch switch is a common part of many electrical appliances, in the use process, there will be a variety of problems, these problems can be better handled, will play a better effect on the use of touch switch.

Touch switch is a kind of widely used switch. Today, electronic work cannot do without it, especially for consumer goods. This kind of switch is widely used in computer, audio, headset, mobile phone, Bluetooth device, eavesdropper, telephone, toy, lamp, fax machine, printer, medical equipment, smart watch, intelligent wearable device, laser pen, mouse, keyboard, induction cooker, TV, DVD, bread machine, electric oven, household equipment and other electronic products.

1: Do you feel any problem by touching the switch?

Many customers have responded, many suppliers sent samples feel very good, but once mass production, the feeling is different. In fact, the problem is very broad. We all know that the handle and key force of the switch are controlled by shrapnel. We often say that shrapnel is divided into phosphor copper shrapnel and stainless steel shrapnel. Now many manufacturers in order to save money, choose phosphor copper shrapnel. The high cost performance of phosphor copper grenade is the reason why it is widely used. However, the temperature of the copper will increase after the temperature changes. The use of stainless steel shrapnel will not have this problem, but the cost of stainless steel shrapnel is relatively high, which leads many manufacturers to choose phosphor copper shrapnel at risk. Therefore, when purchasing light touch switch, we must ask clear questions.

2: Can't touch the switch and press it gently?

Many customers often find that when they press a button, they don't respond. Only when they press the button can they have a functional response. Because our switches are exposed to the air, many products are not sealed and consumer electronics need to be heated. In a humid climate, the spring of the switch is only oxidized. After oxidation, the touch function is not as good as before, which is the problem that light press does not work. Many customers also removed the switch and found a small black spot on the shrapnel. This little black spot is the result of the oxidation of shrapnel. Therefore, it is suggested that the electronic products we do not use should be placed in a monotonous place, and the prepaid electronic parts are oxidized.

3:Touch switch resistance too high?

At present, many customers know little about the resistance of the switch. Generally speaking, our switch resistance is controlled below 30 ohm, so the touch function and life of the switch are excellent. However, some switches have high resistance after furnace temperature and life test. What is the effect of high resistance on the switch? If the resistance is very high, it means that the contact area between the spring leaf and the latch pin of the switch is small, and the small contact area will cause the switch not to contact. If the switch doesn't touch, it will break. So we should be careful about the resistance of the switch. The spring and pin have higher requirements for electroplating and lower resistance after electroplating. If the switch surface is very thin, high resistance will appear after the test.

4: Blistering problem with light Touch switch?

The main data of the switch is our LCP material. After each material supplier provides the material, before injection molding, we will have a process, that is, drying our plastic material, which is also known as quenching. So what is the main purpose of quenching? The purpose of quenching is to dry our plastic materials with moisture and to use our plastic materials to achieve monotonic effects. After quenching, we go to the next process, that is, injection molding process. After that, we will assemble and inspect our products, then package and ship them.

After so many processes, why does our light touch switch blister after passing through the furnace? Let's look at the picture on the left. Our switch bubble is still very serious. In fact, the problem is simple. Our SMD process produces high temperatures. LCP material itself is a kind of high temperature resistant product, which is very suitable for the data of SMD process. The problem lies in the quenching of our first process. If the data of our plastic materials are not completely dried during quenching, our plastic materials will have a certain amount of moisture, which will be carried out in the next process. If there is no high temperature operation, it is difficult to find that it will blister, so we will carry out PCB test during the inspection process.